Materials: Typical materials of molybdenum wire mesh

| PROPERTY |

| Atomic Number |

42 |

| Atomic Weight |

95.94 |

| Density (20°C) |

10.22 g/CC |

| Melting Point |

2896 K, 2610°C, 4753°Fm |

| Boiling Point |

4912 K, 5560°C, 8382°F |

| Coefficient of Thermal Expansion (20°C) |

4.9 x 10-6/°C |

| Electrical Resistivity (20°C) |

5.7 microhms-cm |

| Electrical Conductivity |

30% IACS |

| Specific Heat |

.061 cal/g/°C |

| Thermal Conductivity |

.35 cal/cm2/cm°C/sec |

| Modulus of Elasticity (20°C) |

46 x 106 psi |

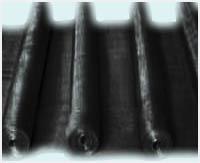

Process

Weaving pattern:

1.Plain weave

2.Twill weave

Surface Finishing: NA

Key Properties

- Low co-efficient of thermal expansion (5.1x10-6 m/m/°C) which is about half that of most steels

- Good thermal conductivity

- Good electrical conductivity

- Good stiffness, greater then that of steel (Young’s Modulus 317MPa)

- High melting point (2615°C)

- Good hot strength

- Good strength and ductility at room temperature

- High density (10.2 g/cm3)

Typical Applications:

In the present section the focus is on grades and properties of Mo containing alloy steel and iron. End uses cover the whole world of engineered products for:

- Automotive, shipbuilding, aircraft and aerospace

- Drilling, mining, processing

- Energy generation, including boilers, steam turbines and electricity generators

- Vessels, tanks, heat exchangers

- Chemical & Petrochemical processing

- Offshore; Oil Country Tubular Goods (OCTG)

Specifications

2mesh/inch-500mesh/inch General;

We produce wire cloth in all kinds of forms. The weaving style is determined according to our customers’ specific requirements, such as the material, the wire diameter, the size of the mesh, width and length.